- Home Page

- Company Profile

-

Our Products

- Valve Components

- RETAINER RING 44 FOR DOUBLE OFFSET BUTTERFLY VALVE

- WEDGE PIN

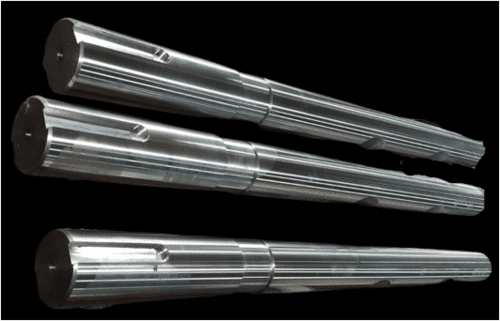

- STEM 42 inches

- STEM 76 inches

- TRIPPLE offset Retainer Rings

- STEMS UPPER or LOWER

- STEM WITH SLOT AND DOUBLE D

- 76 INCHES VALVE STEM WITH RADIUS AND KEY WAY

- Valve Stem

- GUIDE TUBE STEM EXTENSION

- Bottom Plates

- Triple offset Retainer Ring

- 40 INCHES VALVE STEM WITH RADIUS AND KEY WAY

- STEM WITH RADIUS AND DOUBLE D

- STEM FOR BUTTERFLY VALVE

- IMPELLER OR CASING RINGS

- VALVE COUPLING

- Mounting Plates

- RETAINER RING 76 INCHES

- Extended Stem

- STEM FOR NAVAL VALVE NES 833 Material

- VALVE BRACKET

- Stem Bearing

- GLAND FLANGE

- O RING HOLDER

- Automation Work

- JIgs & Fixtures

- Welding Fixture for Voltas Fork Lift Forks

- Fixtures For Connecting Rod

- Fixture For Trunion Suport

- Exhaust Manifold Machining Fixture

- Checking Fixture For Grille Lower Maruti

- Axle Machining Fixture

- Fixture For Suspention Bracket

- Milling Fixture

- TRIPPLE OFFSET VALVE BODY MACHINING FIXTURES

- Stub Axle Or Stearing Knuckle Fixtures

- Inspection Gauge

- Engine Block Hydraulic Fixtures

- Turning Fixture

- Fixture for JCB

- Diesel Engine Connecting Rod

- Fixture For Link-a Frame

- Checking Fixture For Grille Upper Maruti

- Leakege Testing Machine

- Valve Components

- Contact Us

STEM 42 inches

Product Details:

- Usage Industrial

- Material Stainless Steel

- Technique Forged

- Size Customize

- Shape Equal

- Product Type Valve Components

- Color Silver

- Click to view more

X

STEM 42 inches Price And Quantity

- 1 Piece

STEM 42 inches Product Specifications

- Industrial

- Valve, Marine, Generator

- Silver

- Customize

- Equal

- Valve Components

- Forged

- Stainless Steel

STEM 42 inches Trade Information

- 5000 Piece Per Month

- 1 Week

Product Description

A valve stem is the component responsible for transmitting motion to the valves internal part (the disk, ball, or plug), which in turn controls the flow of fluid. The acronym "STEM" is not a standard industry term for a specific type of valve, but instead, describes a key component found in many valve designs. These valves are used across numerous industries for purposes ranging from simple on/off control to precise flow regulation.

Types of stem movement

Valves are categorized based on how the stem moves to actuate the valve.

Linear motion (Multi-turn)

In these valves, the stem moves up and down in a straight line to operate the closure element.

- Rising stem: The stem is threaded and rises out of the valve body as it opens, providing a visual indicator of the valves position. This is common in high-pressure and large-diameter applications.

- Non-rising stem: The stem remains stationary and the valves gate or disc travels up and down on the stems threads, which are inside the valve body. This design is useful in confined spaces or underground installations.

- Sliding stem: These stems slide linearly rather than rotating, and are often used with pneumatic or hydraulic actuators for fast, automated control.

Durable Stainless Steel Construction

Our STEM 42 inches is crafted from premium stainless steel using advanced forging techniques. This guarantees long-lasting performance, enhanced mechanical strength, and superior resistance to corrosion, making it ideal for heavy-duty industrial environments across multiple sectors.

Customizable for Diverse Applications

Whether for valves, marine equipment, or generators, the customizable size and equal shape of our STEM ensure a perfect fit for your specific requirements. As specialists in industrial solutions, we offer tailored products to optimize functionality and efficiency.

FAQs of STEM 42 inches:

Q: How can I customize the size of the STEM 42 inches for my specific application?

A: You can specify your size requirements during the ordering process. As manufacturers and suppliers, we accommodate custom dimensions to ensure precise compatibility with your valve, marine, or generator systems.Q: What process is used to manufacture the STEM 42 inches?

A: The STEM is manufactured using a forging technique, which enhances its strength and durability. This method produces a component with superior mechanical properties, ensuring reliable performance even in demanding industrial conditions.Q: When is the STEM 42 inches typically used in industrial settings?

A: The STEM is commonly used during installation, maintenance, or replacement of critical components in valves, marine systems, and generators. Its robust construction makes it suitable for both routine operations and high-stress scenarios.Q: Where can this STEM 42 inches be utilized most effectively?

A: This STEM is most effective in industrial environments where reliability and resistance to corrosion are crucial, such as marine infrastructure, valve assemblies, and power generation units.Q: What are the main benefits of choosing a forged stainless steel STEM?

A: A forged stainless steel STEM provides high tensile strength, excellent corrosion resistance, and extended service life. These properties reduce maintenance needs and downtime, delivering significant operational advantages.Q: How does the supplier ensure quality during STEM production in India?

A: Quality is ensured through stringent material selection, precision forging processes, and detailed inspections. As exporters, manufacturers, and suppliers in India, we adhere to international standards to consistently deliver high-quality components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email