- Home Page

- Company Profile

-

Our Products

- Valve Components

- RETAINER RING 44 FOR DOUBLE OFFSET BUTTERFLY VALVE

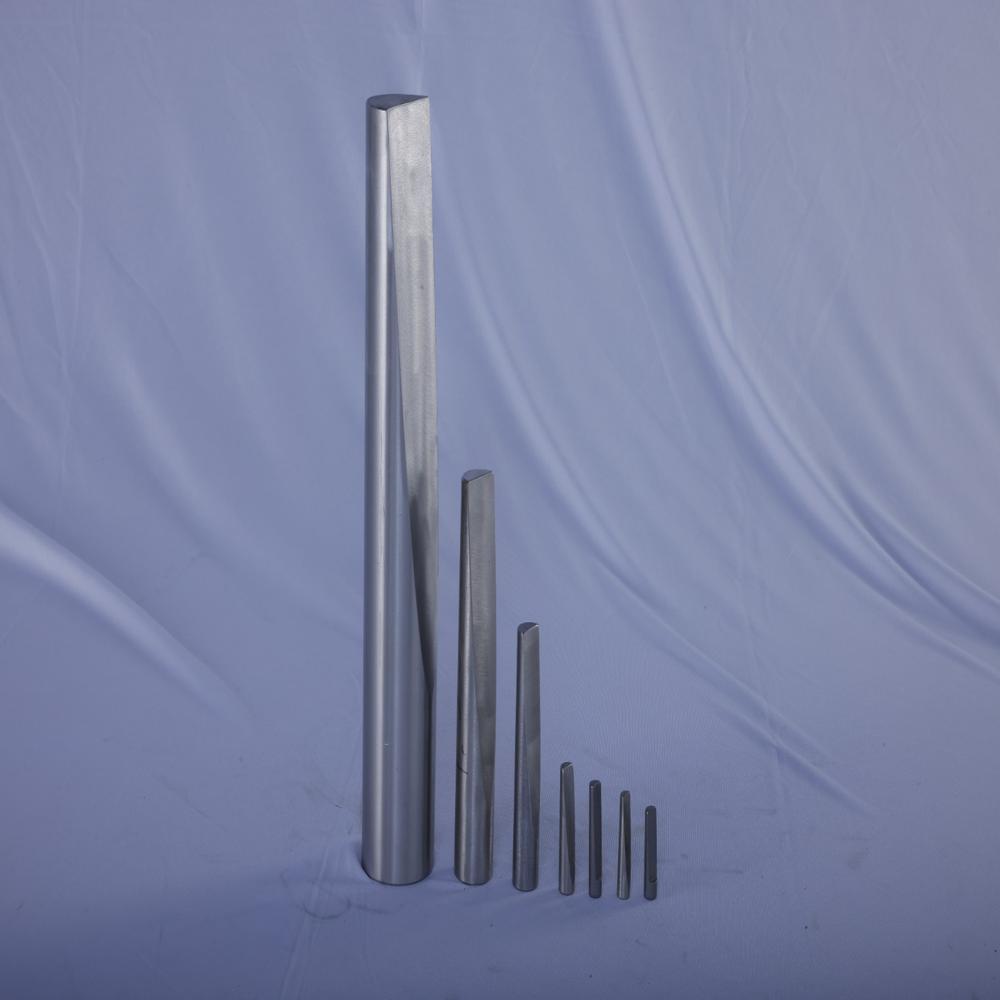

- WEDGE PIN

- STEM 42 inches

- STEM 76 inches

- TRIPPLE offset Retainer Rings

- STEMS UPPER or LOWER

- STEM WITH SLOT AND DOUBLE D

- 76 INCHES VALVE STEM WITH RADIUS AND KEY WAY

- Valve Stem

- GUIDE TUBE STEM EXTENSION

- Bottom Plates

- Triple offset Retainer Ring

- 40 INCHES VALVE STEM WITH RADIUS AND KEY WAY

- STEM WITH RADIUS AND DOUBLE D

- STEM FOR BUTTERFLY VALVE

- IMPELLER OR CASING RINGS

- VALVE COUPLING

- Mounting Plates

- RETAINER RING 76 INCHES

- Extended Stem

- STEM FOR NAVAL VALVE NES 833 Material

- VALVE BRACKET

- Stem Bearing

- GLAND FLANGE

- O RING HOLDER

- Automation Work

- JIgs & Fixtures

- Welding Fixture for Voltas Fork Lift Forks

- Fixtures For Connecting Rod

- Fixture For Trunion Suport

- Exhaust Manifold Machining Fixture

- Checking Fixture For Grille Lower Maruti

- Axle Machining Fixture

- Fixture For Suspention Bracket

- Milling Fixture

- TRIPPLE OFFSET VALVE BODY MACHINING FIXTURES

- Stub Axle Or Stearing Knuckle Fixtures

- Inspection Gauge

- Engine Block Hydraulic Fixtures

- Turning Fixture

- Fixture for JCB

- Diesel Engine Connecting Rod

- Fixture For Link-a Frame

- Checking Fixture For Grille Upper Maruti

- Leakege Testing Machine

- Valve Components

- Contact Us

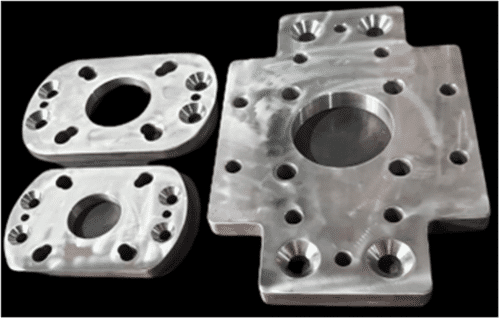

Mounting Plates

Product Details:

- Material Stainless Steel

- Usage Industrial

- Technique Forged

- Size Customize

- Shape Equal

- Product Type Valve Components

- Color Silver

- Click to view more

X

Mounting Plates Price And Quantity

- 1 Piece

Mounting Plates Product Specifications

- Equal

- Customize

- Forged

- Valve, Marine, Generator

- Industrial

- Valve Components

- Silver

- Stainless Steel

Mounting Plates Trade Information

- 5000 Piece Per Month

- 1 Week

Product Description

Mounting plates for valves, also known as subplates or manifold bases, provide a secure and organized interface for installing and connecting valves and other components within a fluid power system. They streamline system assembly, improve serviceability, and can reduce the number of hoses and fittings required, thereby minimizing leak points.

Key functions and benefits

- Centralized mounting: A single mounting plate can serve as a centralized hub for multiple valves, manifolds, regulators, and other components, especially in pneumatic and hydraulic systems. This simplifies the overall layout and improves system organization.

- Reduced leak potential: By using pre-drilled plates with internal porting (manifold bases), the need for external plumbing with numerous fittings is reduced. This results in a more compact system with fewer potential leak points.

- Simplified installation and maintenance: Mounting plates make it easy to install or replace valves without having to disrupt the entire piping system. This modular approach reduces downtime and simplifies maintenance tasks.

- Interface standardization: Standardized mounting plates, such as those compliant with ISO 4401 or ISO 5211, ensure compatibility between valves and actuators from different manufacturers. This is particularly useful for direct-mount actuators on ball or butterfly valves.

Precision Forged for Strength and Reliability

These mounting plates are produced using modern forging techniques, ensuring consistent quality, impressive strength, and long-lasting performance even in demanding environments. Their equal shape design facilitates uniform load distribution across applications.

Customized Solutions for Industrial Applications

We offer mounting plates in customizable sizes to meet specific requirements for valves, marine projects, and generator installations. Their versatility makes them ideal for various industrial sectors that need reliable and precise mounting components.

FAQs of Mounting Plates:

Q: How are these stainless steel mounting plates installed in valve, marine, and generator systems?

A: Installation involves securely bolting or welding the mounting plates onto the designated surface, ensuring alignment according to the systems specifications. Our customizable options allow for seamless integration into a variety of equipment and industrial setups.Q: What advantages does the forged stainless steel technique provide for the mounting plates?

A: The forging process enhances the plates structural integrity, delivering superior strength and resistance to wear, corrosion, and deformation. This makes them especially suitable for harsh marine, valve, and generator environments.Q: When is a customized mounting plate necessary for industrial use?

A: A customized plate is advisable when the application requires specific dimensions, load capacities, or unique configurations not met by standard sizes. Customization ensures optimal fit, safety, and performance for specialized equipment.Q: Where can these mounting plates be used besides marine and generator applications?

A: Beyond marine and generator setups, these mounting plates are versatile enough for use in industrial machinery, heavy-duty valves, construction equipment, and any scenario requiring robust stainless steel mounting solutions.Q: What is the process for ordering customised mounting plates from your company in India?

A: Clients can specify the required size, shape, material grade, and application details. Our team collaborates closely to ensure precise design and manufacturing, with quality control at each production stage before shipment.Q: How do these mounting plates benefit industrial applications regarding durability and longevity?

A: Manufactured from high-quality stainless steel and shaped by forging, these plates exhibit exceptional durability and resistance to corrosion, making them a cost-effective and reliable choice for industries that demand resilient mounting systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free