- Home Page

- Company Profile

-

Our Products

- Valve Components

- RETAINER RING 44 FOR DOUBLE OFFSET BUTTERFLY VALVE

- WEDGE PIN

- STEM 42 inches

- STEM 76 inches

- TRIPPLE offset Retainer Rings

- STEMS UPPER or LOWER

- STEM WITH SLOT AND DOUBLE D

- 76 INCHES VALVE STEM WITH RADIUS AND KEY WAY

- Valve Stem

- GUIDE TUBE STEM EXTENSION

- Bottom Plates

- Triple offset Retainer Ring

- 40 INCHES VALVE STEM WITH RADIUS AND KEY WAY

- STEM WITH RADIUS AND DOUBLE D

- STEM FOR BUTTERFLY VALVE

- IMPELLER OR CASING RINGS

- VALVE COUPLING

- Mounting Plates

- RETAINER RING 76 INCHES

- Extended Stem

- STEM FOR NAVAL VALVE NES 833 Material

- VALVE BRACKET

- Stem Bearing

- GLAND FLANGE

- O RING HOLDER

- Automation Work

- JIgs & Fixtures

- Welding Fixture for Voltas Fork Lift Forks

- Fixtures For Connecting Rod

- Fixture For Trunion Suport

- Exhaust Manifold Machining Fixture

- Checking Fixture For Grille Lower Maruti

- Axle Machining Fixture

- Fixture For Suspention Bracket

- Milling Fixture

- TRIPPLE OFFSET VALVE BODY MACHINING FIXTURES

- Stub Axle Or Stearing Knuckle Fixtures

- Inspection Gauge

- Engine Block Hydraulic Fixtures

- Turning Fixture

- Fixture for JCB

- Diesel Engine Connecting Rod

- Fixture For Link-a Frame

- Checking Fixture For Grille Upper Maruti

- Leakege Testing Machine

- Valve Components

- Contact Us

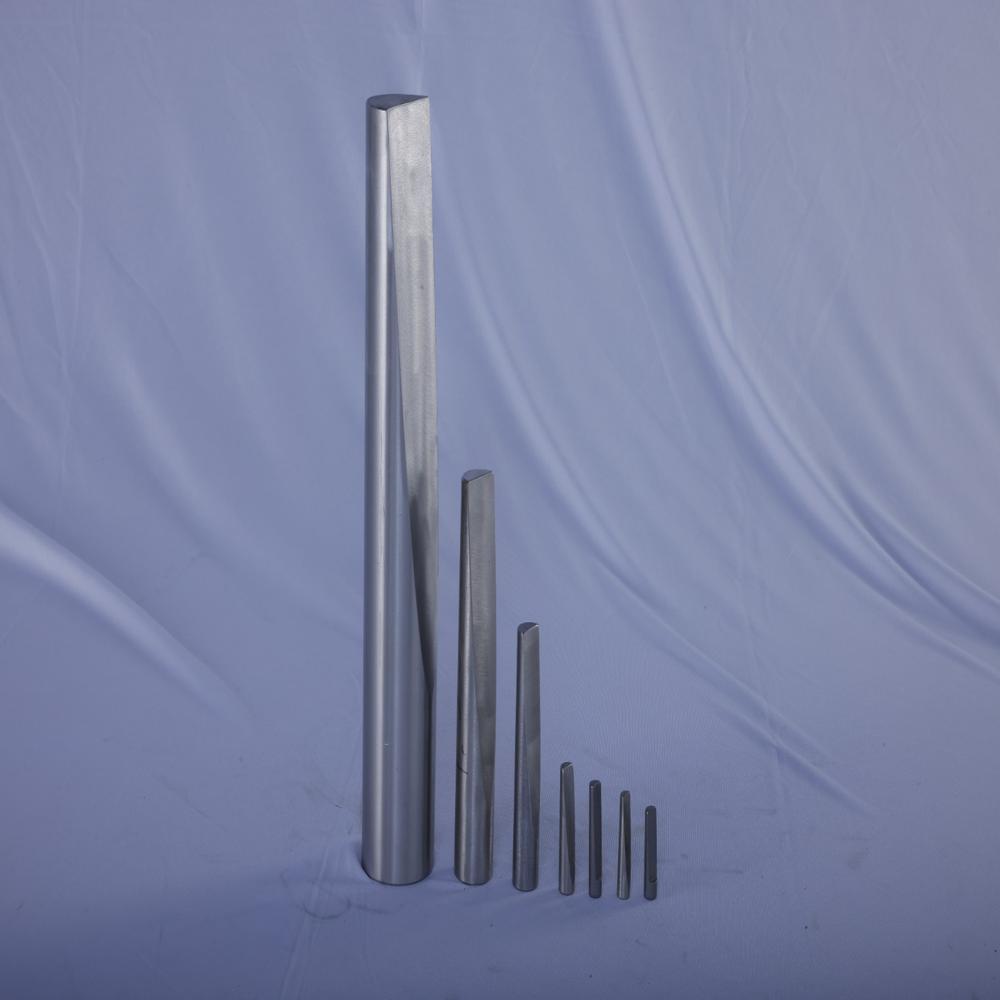

RETAINER RING 76 INCHES

Product Details:

- Usage Industrial

- Material Stainless Steel

- Technique Forged

- Size Customize

- Shape Equal

- Product Type Valve Components

- Color Silver

- Click to view more

X

RETAINER RING 76 INCHES Price And Quantity

- 1 Piece

RETAINER RING 76 INCHES Product Specifications

- Valve Components

- Stainless Steel

- Forged

- Valve, Marine, Generator

- Customize

- Equal

- Industrial

- Silver

RETAINER RING 76 INCHES Trade Information

- 5000 Piece Per Month

- 1 Week

- All India

Product Description

A retainer ring for a valve is a fastener used to hold components, such as a valve seat, stem, or disc, securely in place within the valves body. They act as a shoulder to prevent parts from moving out of position due to pressure, vibration, or other operational forces.

Function and features

- Secures internal components: Retainer rings provide axial retention, which is crucial for preventing the axial movement of a valves internal parts, especially on rotating shafts.

- Ensures tight shutoff: In certain valve designs, such as butterfly valves, a seat retainer ring ensures the correct compression of the valve seat against the disc, which is necessary for a bubble-tight shutoff.

- Vibration and load absorption: The rings help absorb operational vibration and withstand axial loading, which increases the overall efficiency and durability of the valve.

- Cost and size reduction: Using a retainer ring can simplify a valves design and assembly, reducing the need for more complex machining processes like drilling or tapping. This can decrease production costs, weight, and the overall size of the valve.

- Corrosion resistance: In demanding industrial settings, such as oil and gas, the rings are made from special alloys like stainless steel, Duplex steels, or Inconel to withstand harsh, corrosive environments.

Precision Engineered for Industrial Excellence

Our Retainer Ring combines robust forged construction with high-grade stainless steel, delivering exceptional reliability for demanding industrial uses. Whether its for valves, marine machinery, or generator components, these rings maintain structural integrity under intense operational conditions. Custom sizing ensures a perfect fit for your specific application.

Leading Exporter and Manufacturer from India

With decades of expertise in the field, we stand as a premier supplier of retainer rings worldwide. Our facility in India leverages advanced forging techniques and strict quality controls, ensuring every product upholds global standards. We accommodate bespoke requirements and offer timely delivery to international clients.

FAQs of RETAINER RING 76 INCHES:

Q: How are the 76-inch retainer rings manufactured for industrial use?

A: These retainer rings are produced using a precision forging technique. High-quality stainless steel is shaped and treated to ensure maximum strength and resistance to corrosion, making the rings suitable for rigorous industrial applications.Q: What applications are ideal for the Silver Retainer Ring?

A: The retainer ring is designed for use in valves, marine engineering, and generators. Its robust construction and material composition make it an ideal choice for various heavy-duty industrial settings.Q: When should a customized size be selected for a retainer ring?

A: A customized size should be chosen when standard dimensions do not provide a secure fit or meet the assembly requirements of your equipment. This ensures better performance and compatibility with your industrial systems.Q: Where do you export your stainless steel retainer rings from?

A: Our retainer rings are manufactured and exported directly from India. As an established supplier, we distribute to clients worldwide, ensuring prompt and reliable shipping arrangements.Q: What is the process for ordering a custom retainer ring?

A: To order a custom retainer ring, you can provide your specific size and technical requirements. Our team will then consult with you to confirm the design and initiate tailored production, followed by quality testing and shipment.Q: How can the forged stainless steel construction benefit my industrial operations?

A: Forged stainless steel retainer rings offer enhanced durability, resistance to corrosion, and consistent mechanical performance. These benefits result in reduced maintenance needs and greater longevity for your critical equipment.Q: What usage recommendations do you have for these retainer rings in marine or generator applications?

A: Ensure the ring is properly fitted according to your equipments specifications, as proper installation is key to optimal sealing and stability. Regular inspection is recommended, especially in environments prone to high stress or corrosion, to maintain operational reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free